Backyard Foundry E-Zine: Duckie cast in Brass

Posted 12-26-2009

I did this duck as an investment casting. I used a rubber Duckie from the toy store. I glued it to the bottom of a milk carton and poured the investment over it...then burned out the rubber and poured it. I found that the best way to pour this was to pour it open faced. Yes, it did shrink some on the bottom, but that is OK because it is on the bottom! My wife comissioned me to make this for a friend who has a rubber duckie collection.

On some of the ducks I made, I made a silicon mold of the duck and poured wax into it to make the pattern. That way, I have a pattern that I can easily make again. The duck I am showing on this page was made with one of these wax patterns.

Past E-zines

CNC Router

(Click on picture to visit page)

Pewter Bell Video

(On my Yuwie page)

Swedish Horse

Lost Foam Cast in Brass

Search my site here!

Here it is in it's natural habitat!

I left it a rough finish...I think the texture makes it look antique.

Guest book is for this page only...and is public...so only add info you are comfortable with!

E-mail me if you have private comments or suggestions

Video of Lost Foam pour

This site is for adults only. The things shown here can be very dangerous so please don't try anything shown here without learning more about the risks and safety precautions required. :) In other words, don't blame me if you hurt yourself!

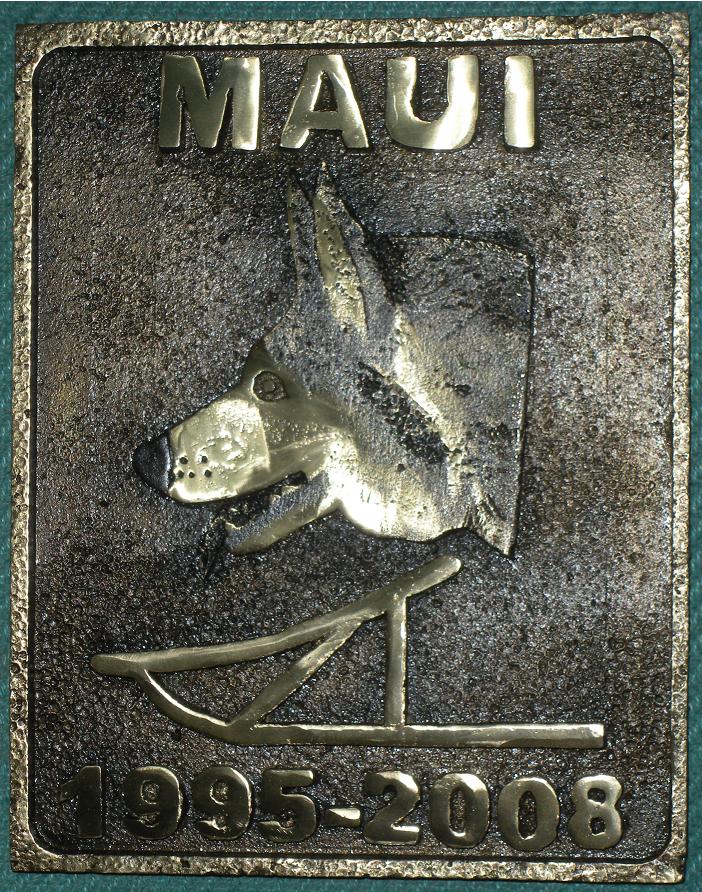

Dog Plaque

Lost Foam Cast in Brass

Here it is as poured

Here is the silicon mold

I used a juice bottle for the flask.

Here are some investments burned out

The "tin" can is a great way to do a wax investment. Leave the lid on one end...pour a little wax in and sit your wax pattern into the wax. Then pour your investment over it and when set up, take a can opener and cut off the other end of the can. (the one in the can is NOT the duck by the way!)

Elephant

Lost Foam Cast in Brass

Here is a Plaque that I did using lost foam...I didn't take pictures of the whole process this time though.

Side 2